Categories

Recent Posts

Tags

Model No. OMG Features: Beam angle: 15/30/45°, Frosted PC Cover, New Design; Material: Die-cast Aluminum+Frosted PC Cover; Dimmable Options: Triac / 0-10V / 1-10V / DALI / DMX512; Dimmer: Touch Screen Dimmer / Rotatable Dimmer; Model No. Power Lumen (lm) Driver Brand LED Style CCT(K) Beam Angle Input Voltage (VAC) CRI Size(m1

Model No. WHB-Adjustable Reflector color: Matt White/Black; Features: Adjustable/Fixed; Honeycomb Cover Available Material: Die-cast Aluminum + Reflector; UGR<19 Model No. Power Lumen (lm) Driver Brand LED Style CCT(K) Beam Angle Power Factor CRI Size (mm) Cutout (mm) WHA-7W 7W 550lm Lif1

Model No. TD057A- Fixed Downlight IP44 LED Downlight Fixed or Adjustable 10W to 80W Material: Die-cast Aluminum+ Alu Reflector + Full Transparent Glass Cover; Model No. Power Lumen (lm) Driver Brand LED Style CCT(K) Beam Angle Power Factor CRI Size(mm) Cutout(mm) TD057A-2.5F 7W 600lm Philips Tridonic V.S . Lifud Osram CREE Cit1

Model No. SG Features: Beam angle: 15/24/36°; Angle Adjustable ; Material: Die-cast Aluminum+ Reflector+Lens; Dimmable Options: Triac / 0-10V / DALI / ; Model No. Power Lumen (lm) Driver Brand LED Chip CCT(K) Beam Angle Power Factor CRI Size(mm) Cutout(mm) SG-2.0 5W 400lm Lifud Philips Osram 1

As a factory, we know very well to make a completed lamp. COB LED Downlight is the most easy one. We will tell you exactly how to make it.

Firstly, you need to know the lamp size to cut the wires(red and black) acordingly. If you got the COB LED at the first, test them lighting or not, then you can do soldering onto the COB at the "+" and "-", then solder the wires on the COB, red is to "+", black to "-".

|

|

Secondly, in order to get good heat dissipation and keep long working, we need to stick some Heat-Conducting Silicone Grease onto the PCB board,the back size of the COB.

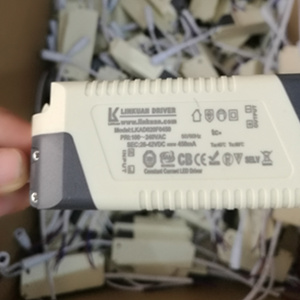

Thirdly, stick the COB onto the lamp heat sink properly, then put the LED Holder onto the COB rightly and the holder hole well to the screw hole, then fix the led holder to the COB,besides, the red and black wire put together to connect to the male side of the led connector after it was through the hole, then use led driver to test the lamp lighting or not.

|

|

Fourthly, put the aluminum reflector to the led holder, and opal diffuser cover to the reflector, then the outer trim to the cover, turn over the lamp, use screw to fix the heat sink onto the outer time.

Fifthly, use the cable holder to press the male side onto the lamp tightly with 2 screws, then you can use the led driver female side to connect male side,then test the whole lamp.

|

|

So above all, there are 3 times to test the light lighting or not. And it's so easy right ? So if you want high quality then depends on the below factors: COB chip, heat-conducting silicone grease, wires, heat sink thickness, spring clips,screws and led driver. The most important to decide the lifespan is the COB and led driver. If you have any questions in assembling a product, just send us mail. We have another type LED COB downlight IP54.

WeiYe Optoelectronic Technology Co., Ltd.

Tel/Fax: +86 755 2737 0606

Mob: +86 134 8074 0318(Whatsapp)

Skype: lhwyled

Email: info@aku-led.com

Web: www.lhwyled.com

The professional team service!